In the world of modern manufacturing, where precision and dependability are not a matter of debate the spindle is one of the key elements in any machining system. Whether it’s carving aerospace-grade alloys or fine-tuning high tolerance components for medical devices the machining spindle will be the hidden force behind precision, speed, and the utmost consistency.

Elite spindle makers like POSA are leading this specialized sector, redefining the quality and endurance of industrial machining environments.

The Spindle is the core of the Machine

Spindle quality is the determining aspect in any CNC machine. The spindle drives the tool with high precision, stability and torque. An unbalanced or poorly designed spindle isn’t only the result of faulty parts it can damage the machine, cut down on the lifespan of the tool, and knock off the entire production process.

Image credit: posa-spindle.com

Precision spindle technology can make a huge difference. Precision spindles, in contrast to standard parts, are engineered, examined and calibrated carefully to meet the demands of extreme and high-demand conditions.

POSA Machinery: More Than Just a Spindle Manufacturer

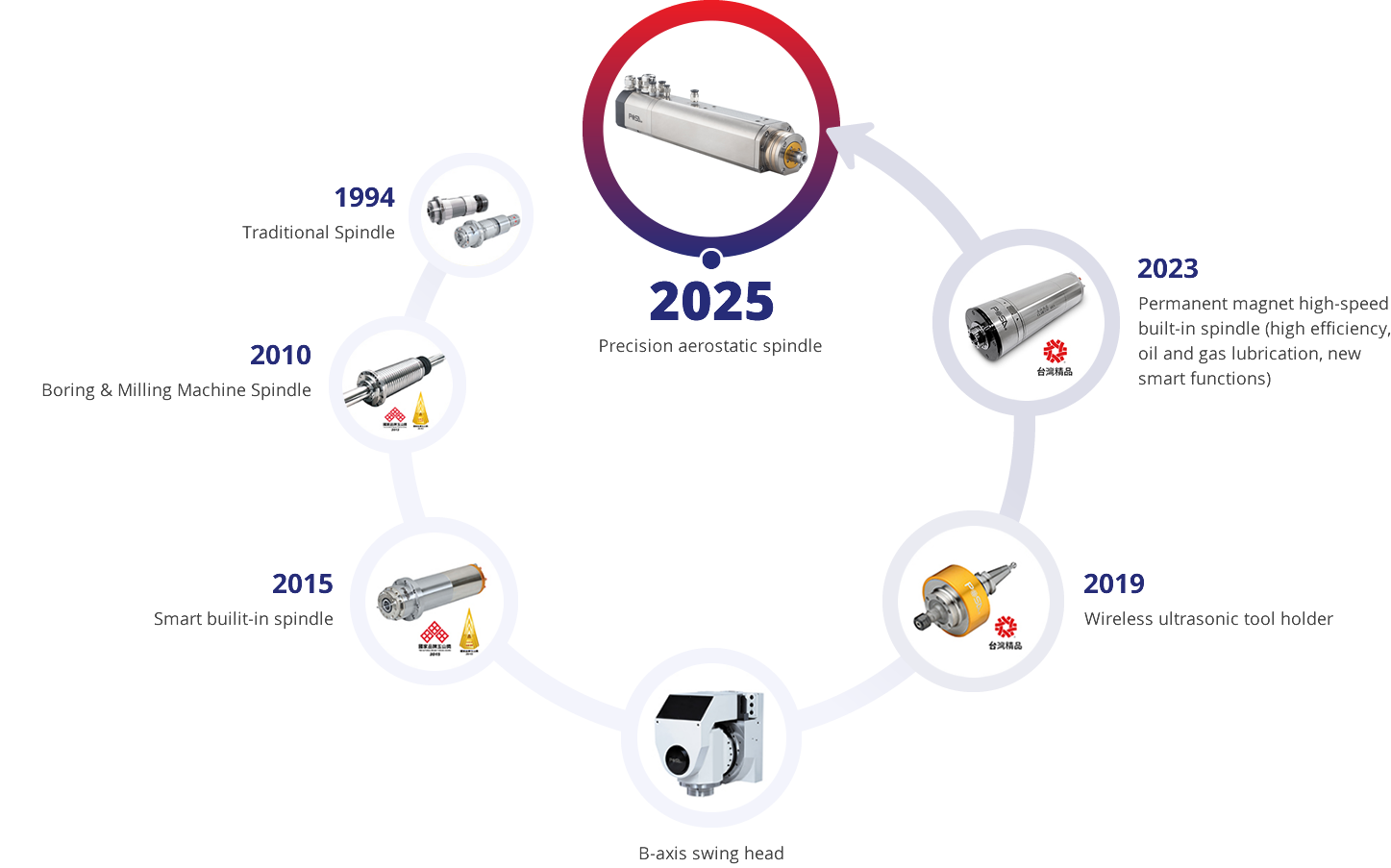

POSA Machine has been an innovator in the manufacture of spindles for many years. While many spindle makers claim to be precision-made but they don’t have the experience and technical expertise POSA has gained over those years. Spindles made by POSA are famous for their stringent in-house quality control procedures and rigorous tests. They also craft solutions that perform to meet the varied needs of modern-day industry.

POSA spindles have been employed in grinding machines for tool that are vertical and horizontal in machining center, heavy-duty material removal applications. Each spindle is subject to a stringent R&D procedure that is focused not just on the functional aspects of the spindle, but on its durability as well as thermal stability.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has witnessed incredible innovation in the last few years. Spindles today are more than simply a shaft that rotates. They are equipped with sensors and cooling systems as well as an intelligent balance mechanism. POSA CNC lathe spindles allow the machinists with flexibility when handling soft materials and hard metals, without compromising the precision. With their advanced ceramic bearings as well as high-quality construction, these spindles ensure tight tolerances over extended runs. This kind of durability translates directly into improved part quality and decreased downtime.

Custom-designed Machining Spindles to meet Real-World Needs

There’s no universally-fit-all spinning machining machine, particularly in industries like mold and die manufacturing and aerospace, automotive. POSA is aware that each industry has its own specific requirements, whether it’s spindle speed, load capacity, or resistance to environmental conditions. This is the reason POSA provides customized spindle designs, based on the needs of each client. POSA is able to provide the support for engineering and flexibility that modern manufacturing companies need, whether developing a vertical milling machine or incorporating a higher-frequency spindle within a compact unit.

More than Machines: A Dedication to Craftsmanship

POSA is not only about its spindles, but also the underlying concept behind these spindles. The POSA philosophy is a blend of craft and ingenuity. The design engineers collaborate with clients to understand their requirements, listen to them and continuously develop their products. In an era when machine uptime, precision and consistency can decide the fate of the efficiency of a line, finding the right spindle partner is crucial.

Final Thoughts

The future of manufacturing isn’t solely about more efficient machines, but also more intelligent and more reliable components. POSA Machinery is an excellent example of the results that can be achieved by spindle manufacturers that blend technical knowledge with a concentration on customer service. Whether you need a high-performance CNC lathe spindle, a heavy-duty machining spindle, or a finely tuned precision spindle, choosing the right spindle isn’t just a detail it’s a decision that shapes everything downstream.